Calcium silicate insulation materials are generally composed of lime, siliceous raw materials, etc. They have the characteristics of good fire protection, waterproof, light weight, high strength, long service life, heat insulation and sound absorption, and are widely used in the petrochemical industry.

The company has built a new, intelligent production line, using raw ore wet soil and lime as the main raw materials, specializing in the production of microporous calcium silicate insulation products, with a first-phase production capacity of 60,000 cubic meters. Products of various shapes and specifications can be customized according to customer requirements, and can be used in flat plates, straight pipes, tees, elbows, flanges, insulated pipe supports, etc. to provide customers with efficient, long-term and durable insulation products.

After authoritative testing by a national testing agency, the company's product appearance quality, dimensional deviation, physical properties and other indicators all meet the requirements of the GB/T 10699-2015 "Calcium Silicate Insulation Products" standard, including compressive strength, flexural strength, etc. The measured data of the indicators have reached the top level in the industry.

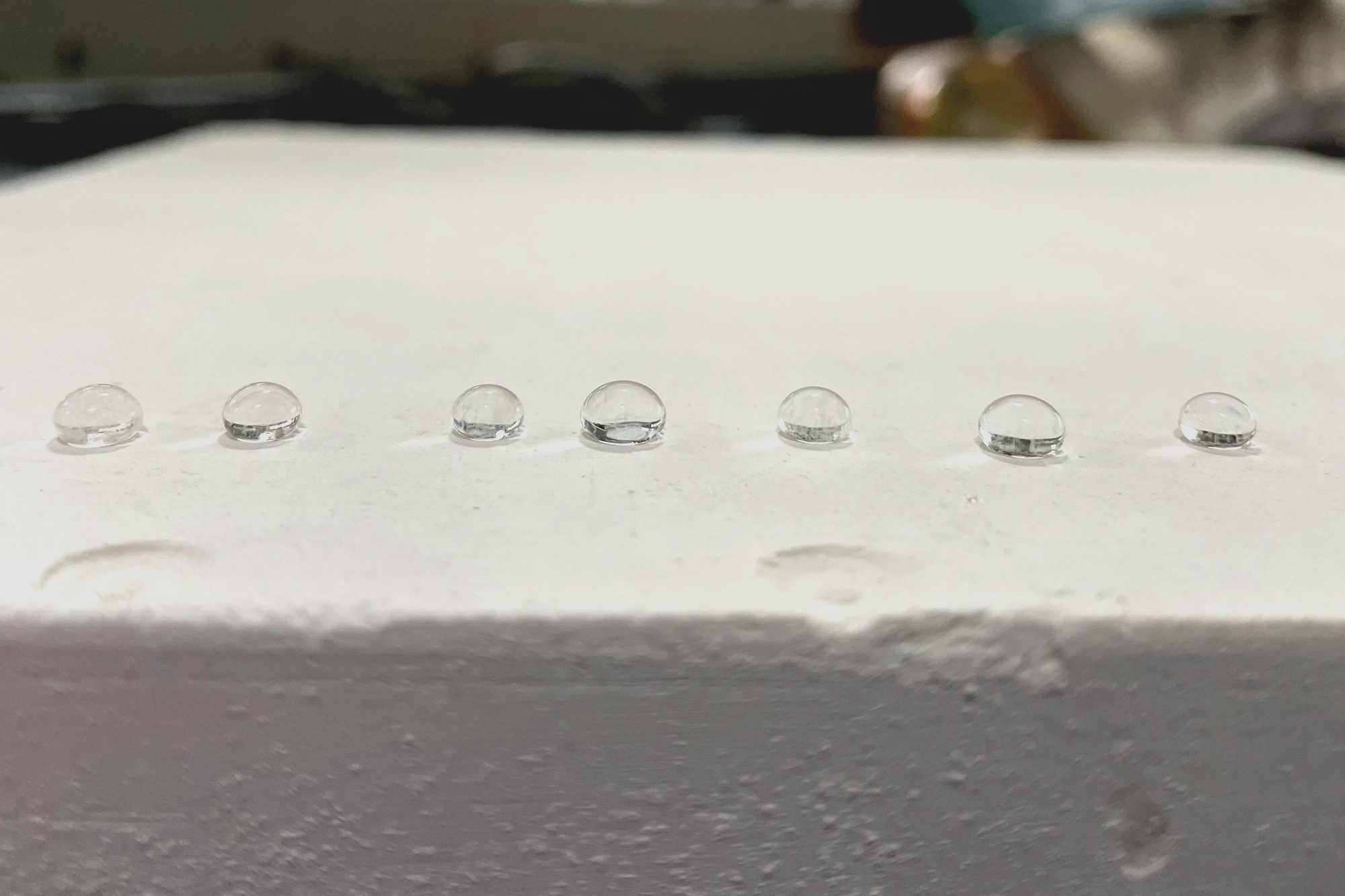

The company has also made breakthroughs in product research and development, successfully developing surface and overall hydrophobic calcium silicate products with a hydrophobic rate of greater than or equal to 99%.

-e547a7ffda1d40499a5ecab5ffd7e7ea.png)

Product specifications

Shells

Length: 610mm, 915mm optional

Pipe diameter: ≥300mm is acceptable

Thickness: ≥50mm is acceptable, if it exceeds 85mm, layering is recommended

Tablet

Length: 610mm, 915mm optional

Width: 200~305mm

Thickness: ≥50mm is acceptable, if it exceeds 85mm, layering is recommended

Features

(1) Uniform microporous structure, light bulk density, high strength and less ash shedding;

(2) Strong durability, with a compressive strength greater than 750Kpa, which can effectively prevent damage from collisions and trampling;

(3) Good damage and water resistance, stable thermal insulation structure;

(4) The volume of a single block is 2.38 times that of traditional products, with good high-temperature performance and long-lasting and stable thermal insulation effect;

(5) It has good anti-corrosion performance and contains a special anti-corrosion agent, which can effectively avoid corrosion under the insulation layer;

(6) Low oil absorption rate, reducing fire risk;

(7) Long service life, stable insulation structure, long-lasting insulation effect, and can be used for more than 30 years;

(8) The installation of customized molded parts is convenient and efficient;

(9) Outstanding effects of energy conservation and carbon reduction